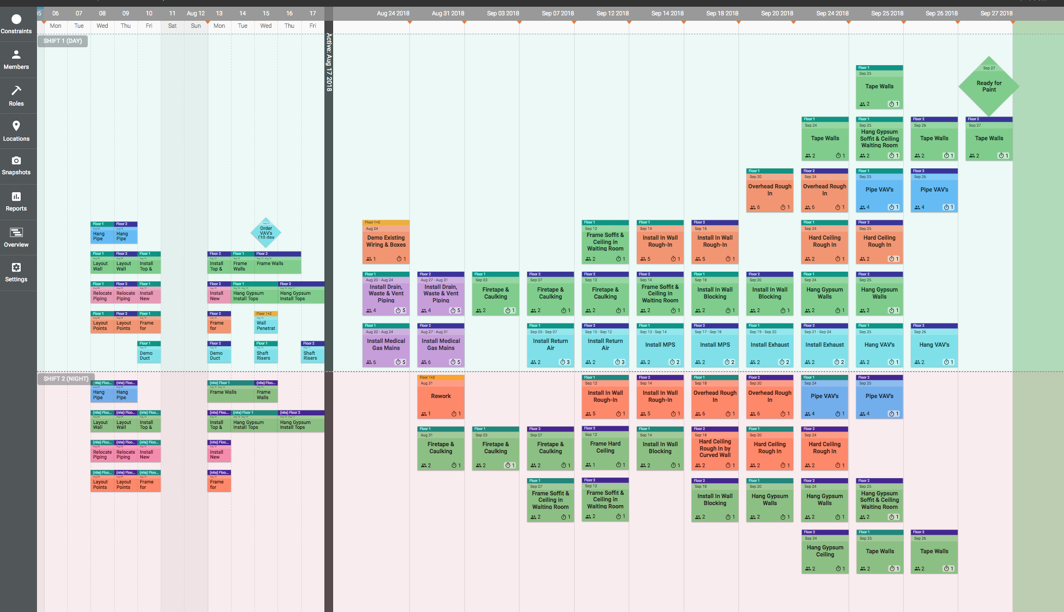

We’re frequently asked, “What’s the best way to manage multiple shifts in Touchplan?” The simple solution is to use a combination of locations and swim lanes. The locations will allow you to sort reports and the day and night shift work will be separated to show manpower reporting for both shifts (see Figure 4). Swim lanes make it much easier to view both shifts in the plan.

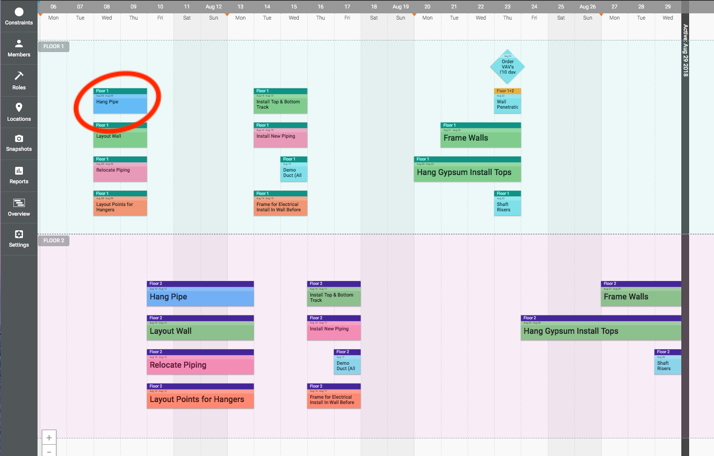

The plan below (Figure 1) is a typical work sequence to rough in two floors of a small building. The team put together this sequence in a pull planning session with all trade foremen creating their work activities.

Figure 1

After creating the pull plan, the team activated the plan and created their three-week look-ahead (Figure 2) for floors one and two.

Figure 2

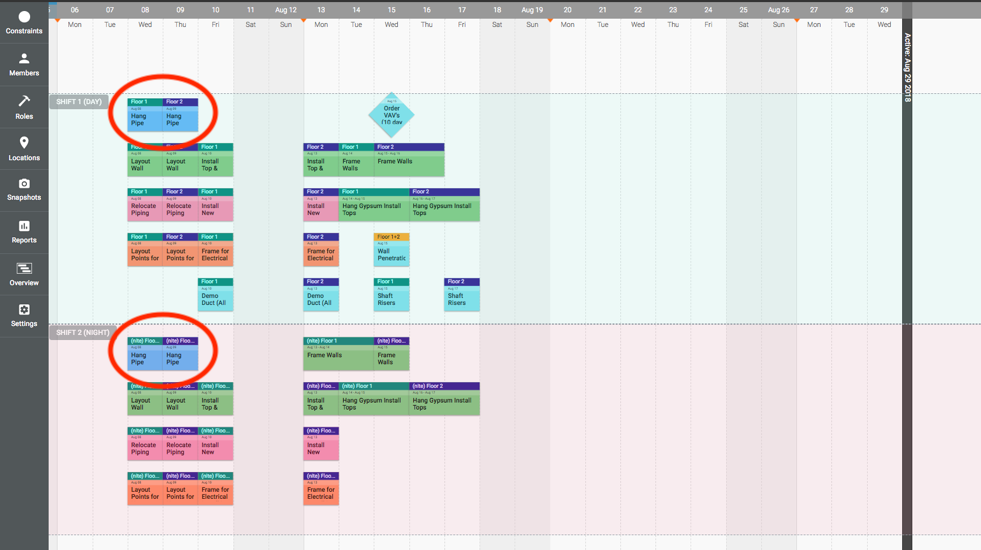

Here’s how the same plan would look running two shifts (day and night). The team agreed that all trades would staff so that they would have a day and night shift. The team took the existing single shift plan and broke the work up into two shifts (Figure 3).

Figure 3

The first major takeaway is that they cut the overall duration in half. Any multi-day activities were spread across both shifts. For example, a two-day task could now be completed in one day using day and night shifts. The task “hang pipe on floor 1” (Figure 2) takes two days in the day-shift-only plan and is scheduled to start on August 8. In the two-shift plan, the same activity begins the morning of August 8 and finishes on the night shift that same day.

Figure 4

Figure 5

The day and night shifts both have nine workers on Wednesday and Thursday, August 8 and 9. The HVAC contractor is the only subcontractor not working nights. This same day/night shift strategy can be used for three or more shifts, or hourly work when your standard work batches are broken down to that level of detail.

The pull planning process will help the team better understand how to best design the flow of work based on their shared understanding of available skilled workers, material supply chains, equipment logistics, and all the other factors related to the work. This is accomplished by framing the planning discussion in terms of satisfying team member needs instead of executing work because it is available. This need-based approach forces a level of negotiation, small-batch design and work balancing. Once the team has a work sequence they agree on, the team can then discuss and plan for multi-shift work to accelerate delivery of the milestone.

For more Lean learning, register for Touchplan’s webinar at the Lean Construction Institute Congress 2018 here.