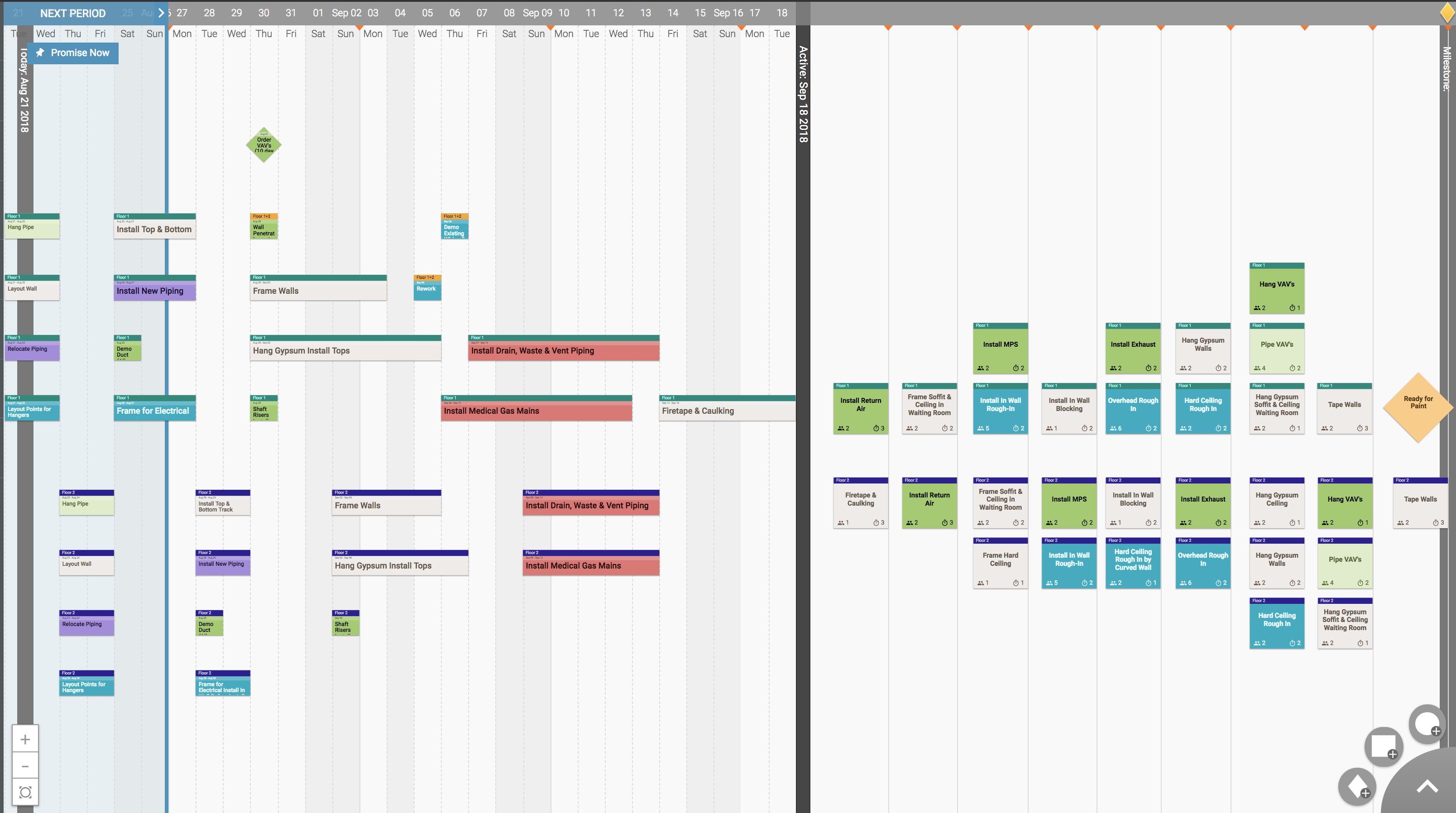

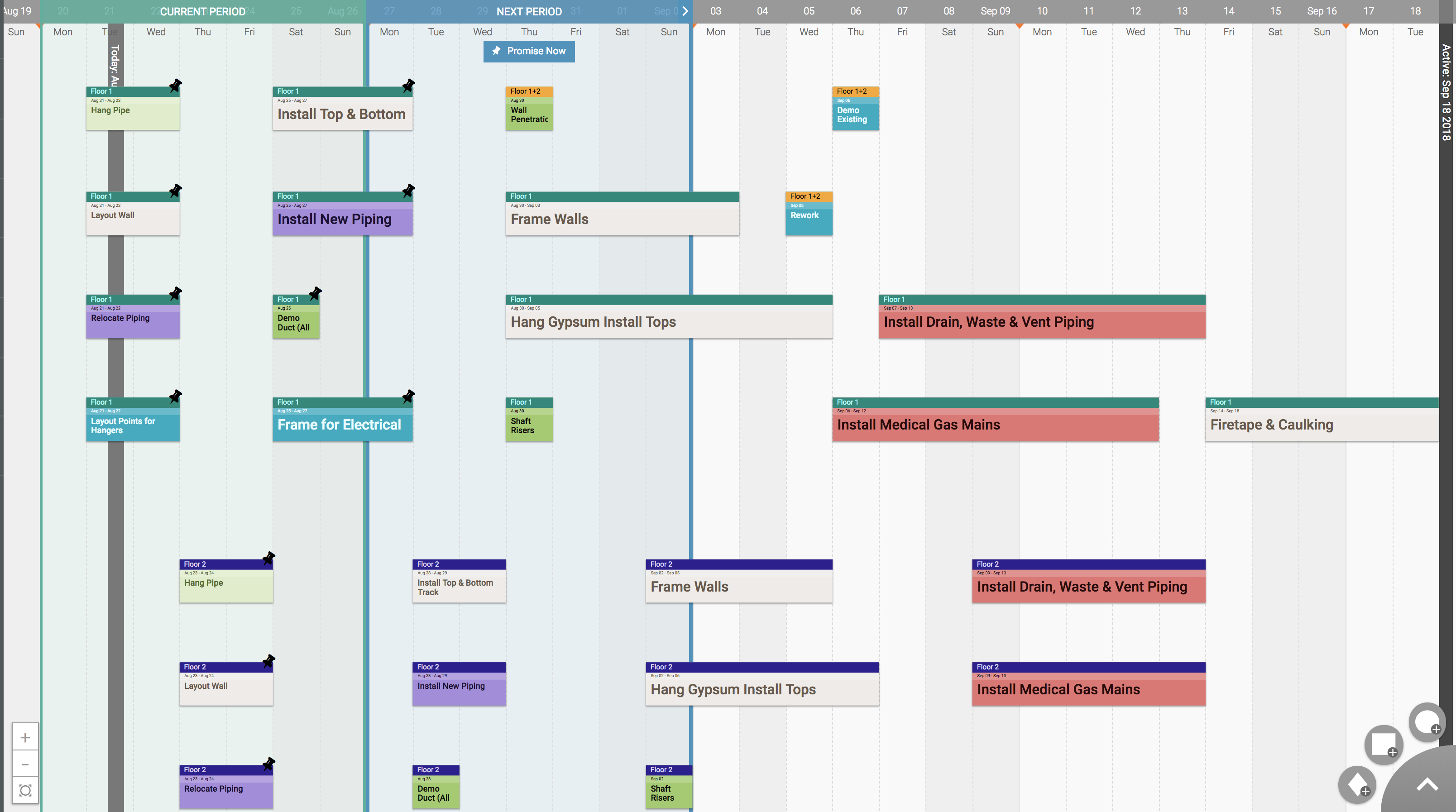

Ever notice how most field project teams don’t use the CPM schedule on the trailer wall to plan or manage their day-to-day activities? It’s just not detailed enough. It’s not flexible enough. It’s rarely current. And it just doesn’t reflect what actually gets done. So what are they doing instead? They’re meeting. Continue reading “How to make a schedule you can actually use”

The IGLC 2016 Conference has the Touchplan crew thinking about Lean Construction and Lean Project Management. We’ve been so focused on talking to you about our smarter planning initiatives that we haven’t discussed Lean in a while. Here is a quick tutorial to explain the whole Lean thing, if you are curious.

Continue reading “What is Lean Project Management?”

The weekly work meeting is your weekly check-in to make sure that everyone is on track to complete their upcoming scheduled work. It is an opportunity for everyone to hear from all team members and obtain their commitments for completing next week’s work. A successful meeting will result in a smooth and steady work flow. Only tasks without any known constraints are included in the Weekly Work Plan. The goal is to explore the links between tasks and prevent team members from overcommitting. Here are some common mistakes to avoid.

Continue reading “Weekly Work Meetings – 4 Common Mistakes”

According to the World Economic Forum’s publication Shaping the Future of Construction–A Breakthrough in Mindset and Technology there is a great need for greater productivity in construction. The last half century saw other business sectors experience surges in productivity, while the advances in construction have been meager at best.

Continue reading “Skanska discovers shipwreck in Boston Seaport District”

According to the World Economic Forum’s publication Shaping the Future of Construction–A Breakthrough in Mindset and Technology there is a great need for greater productivity in construction. The last half century saw other business sectors experience surges in productivity, while the advances in construction have been meager at best.

Continue reading “Productivity Boosts Needed in Construction”

If you already understand the broad terms of what Lean is, then we can get into specifics and look at the six guiding principles of Lean. Remember that the goal of the system is to increase efficiency by reducing waste. We accomplish our money saving goals by improving the means to our ends. These principles outline the necessary steps for creating the right means to create the right end result. They serve as a step-by-step path to most efficiently implement Lean principles in your business. And you want to implement Lean principles because they save you money.

Continue reading “Lean Principles”

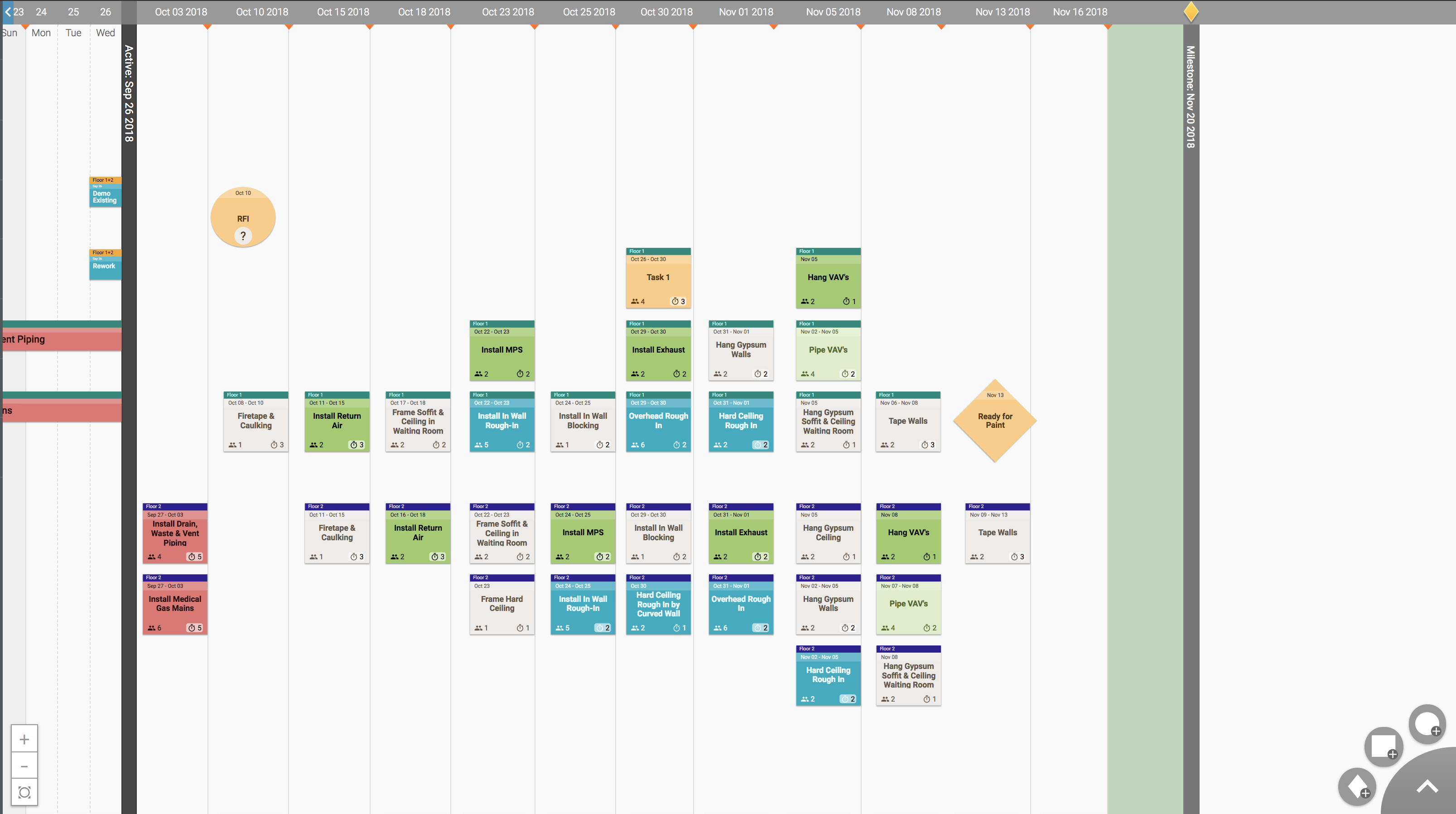

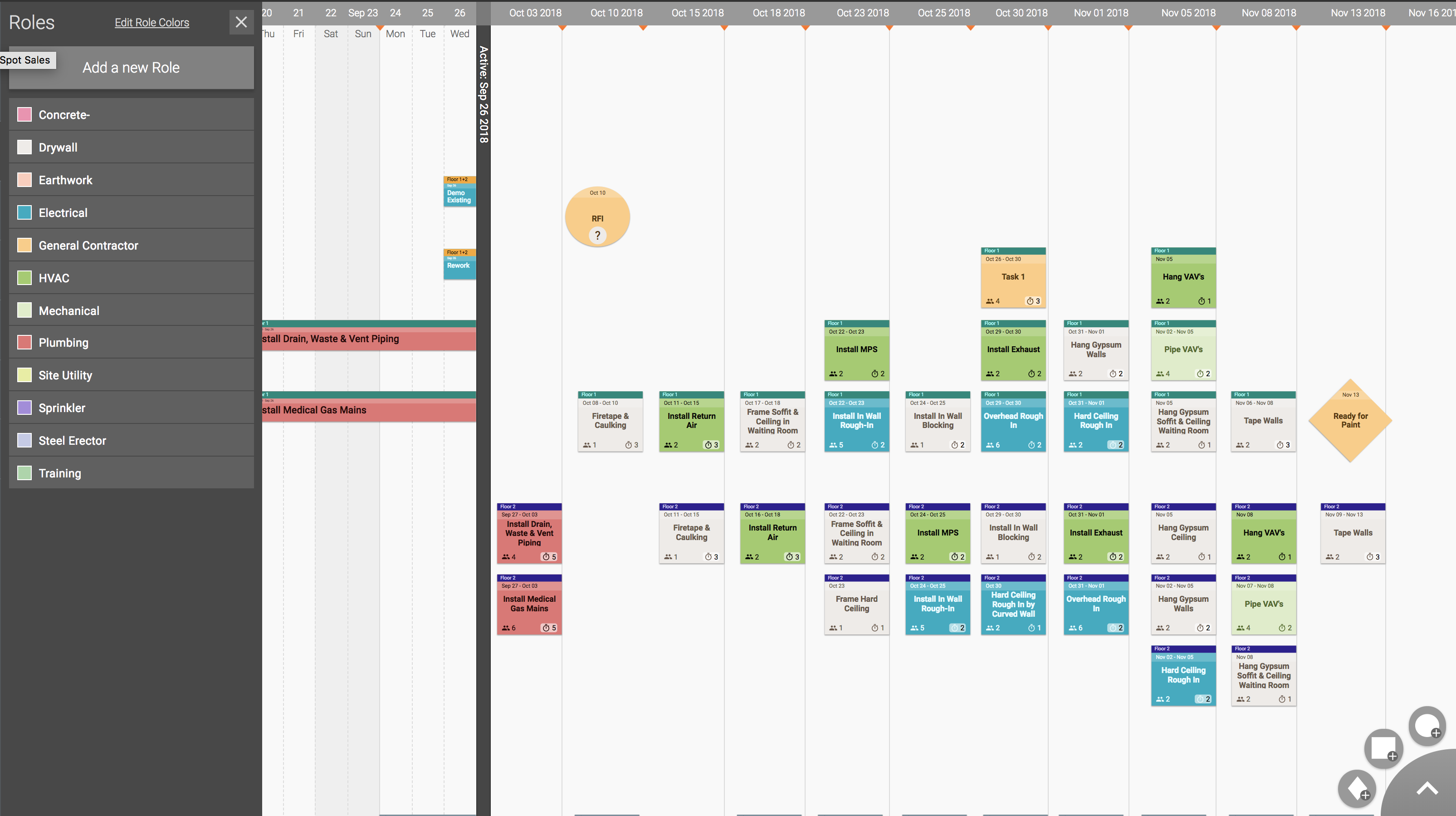

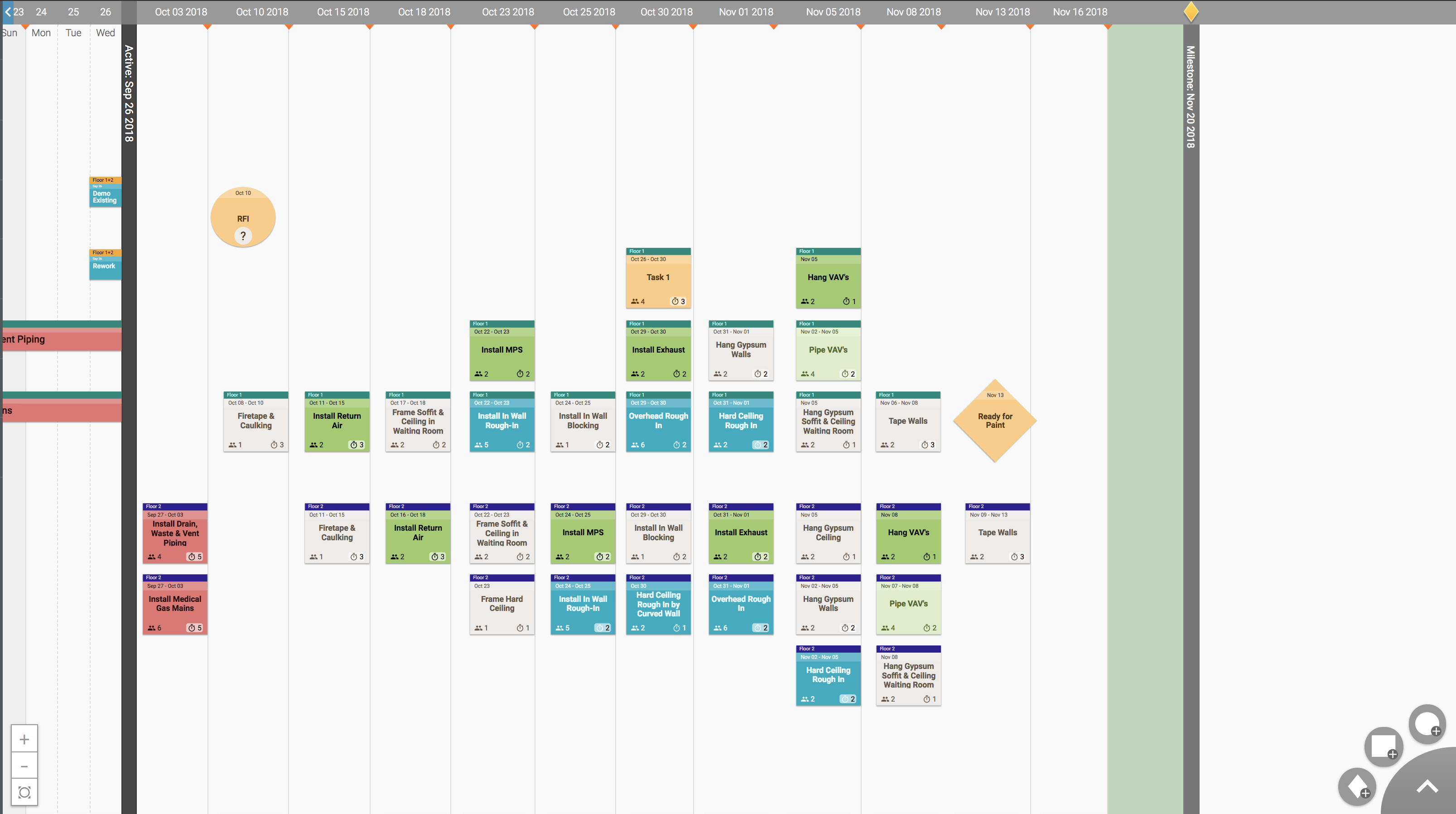

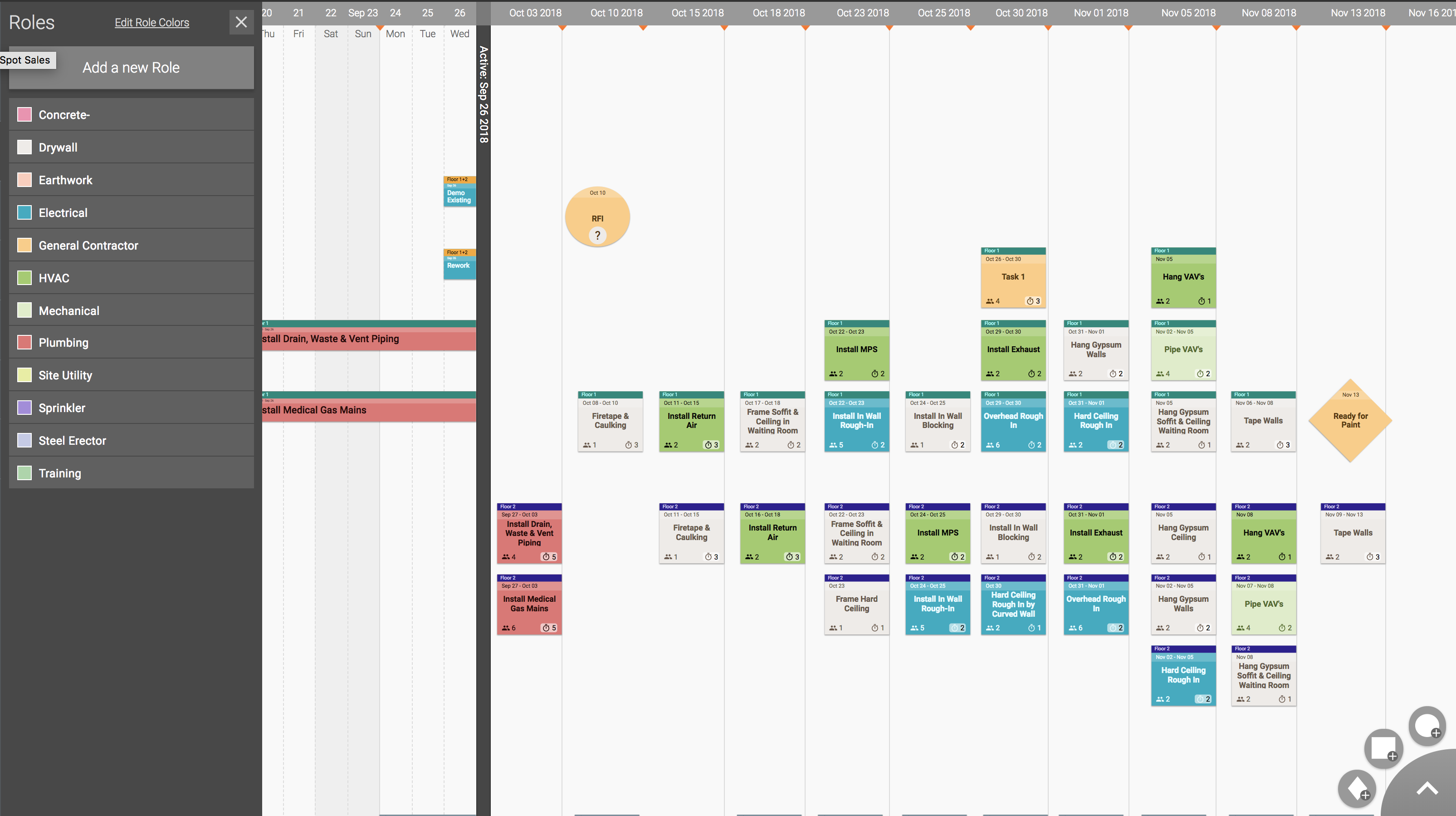

The Last Planner® System, or Last Planner®, is a short-term production planning system designed to produce predictable workflow and rapid learning in programming, designing, commissioning, and construction of projects. The name refers to the person on site who can ensure predictable workflow downstream. Owners, clients or construction companies can use Last Planner® to achieve better performance in design and construction through increased schedule and program predictability.

Last Planner® was developed by Glenn Ballard and Greg Howell.

The five steps of Last Planner® are:

Master Scheduling

To start, identify your high-level project milestones for significant phases of your project, typically six months out. Examples of these milestones would be steel structure topped off, building weathertight, rough-ins complete, site finishes complete, etc.

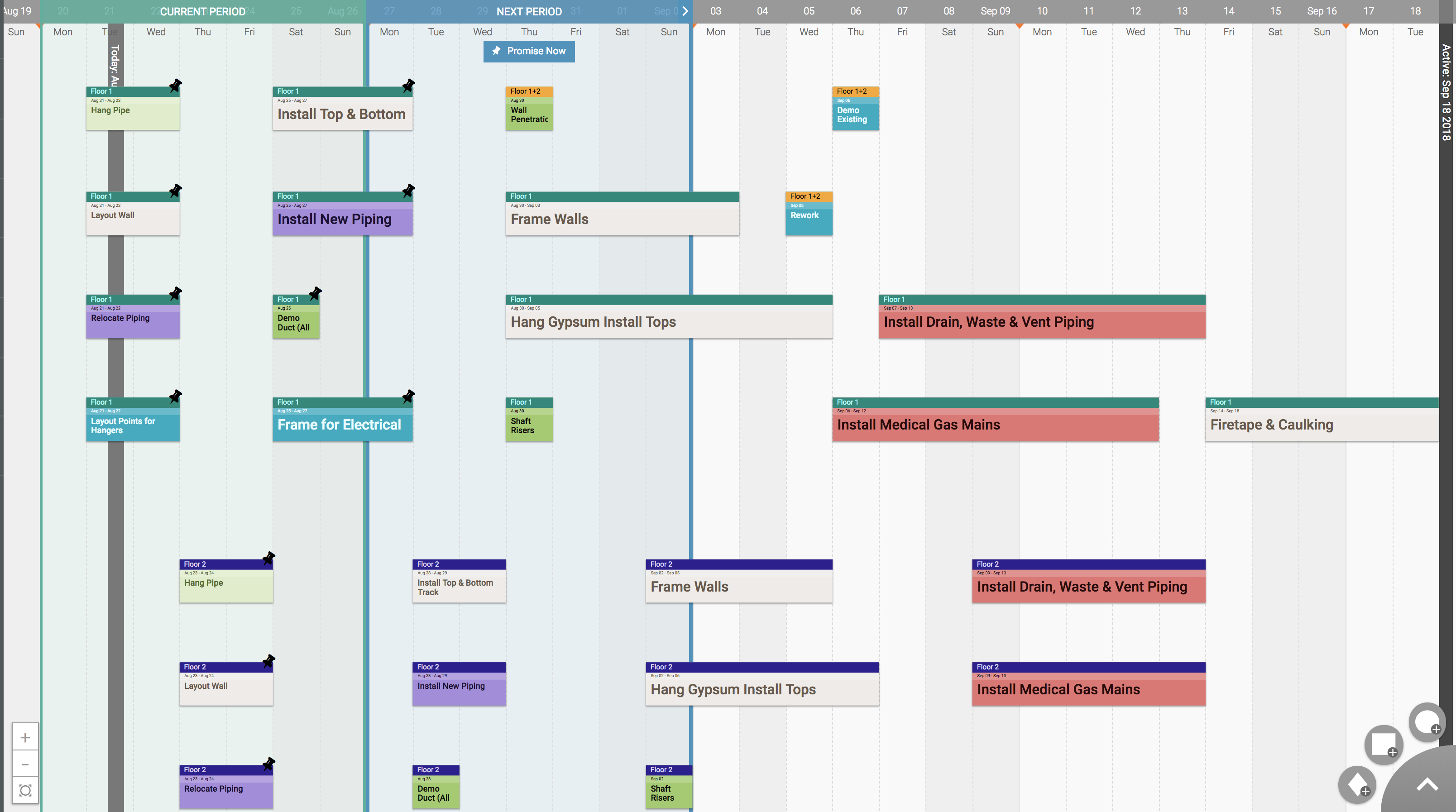

Phase Scheduling

Engage the last planners (foremen and PMs) in pull planning sessions to collaboratively establish the flow of work for the project milestones. Specify handoffs between trades within each phase schedule to ensure smooth and reliable workflow for the next six to eight weeks of work.

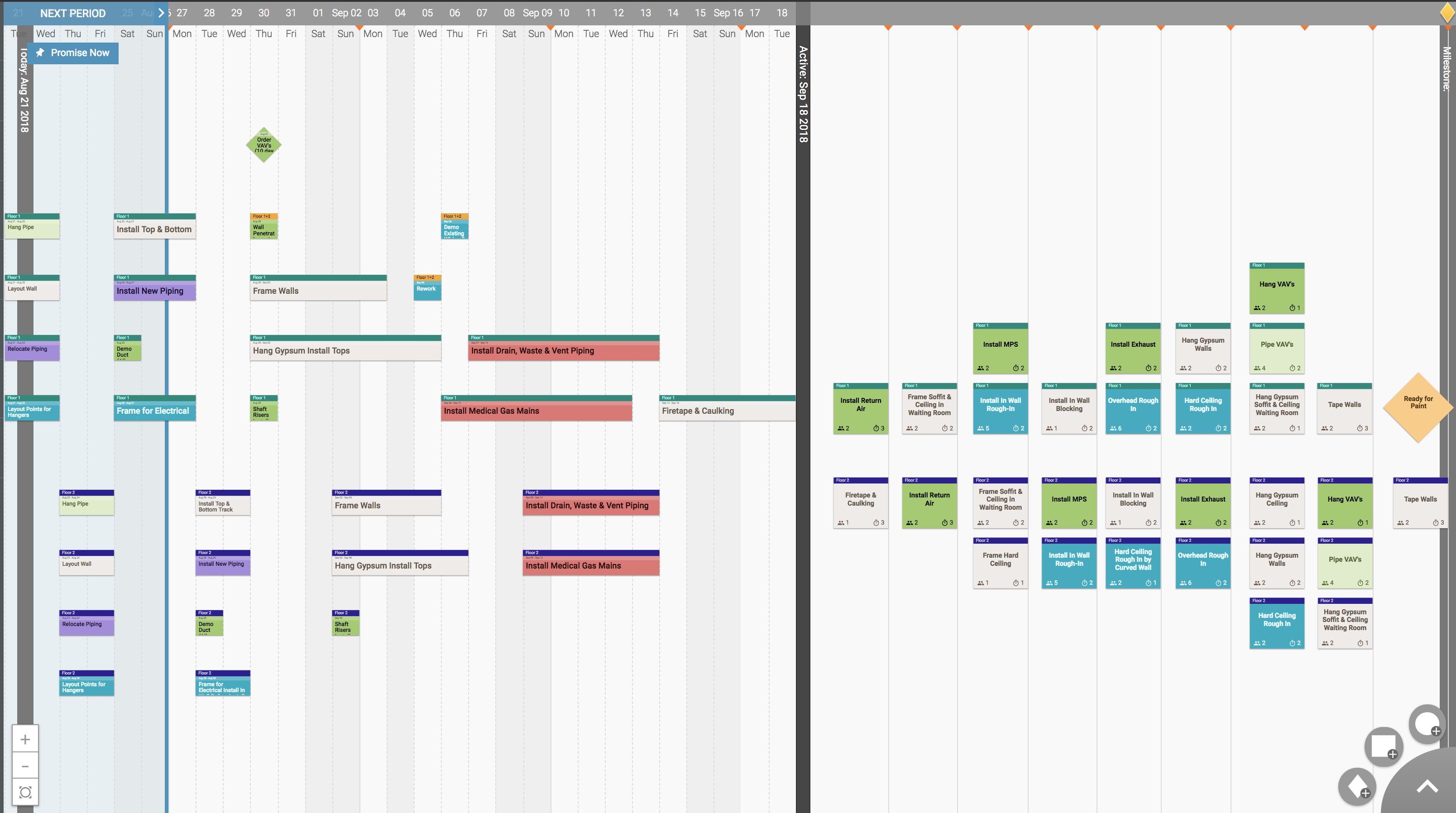

Make Work Ready Planning

This involves looking out several weeks and identifying any constraints that would keep work from starting as scheduled. Review your plan for the upcoming four to six weeks and work collaboratively to make work ready by removing constraints. Promise work for execution in a productive and effective manner and replan as necessary.

Weekly Work Planning

Talk through the upcoming week and make commitments to perform work in a certain sequence. Planners should only promise work that is unconstrained and start work that is ready. Engage the last planners in planning their work from the phase plan through daily coordination.

Learning

Evaluate the successes and failures of the previous week’s plan. Review the percent plan complete (PPC) and variance categories. Identify root causes of plan failures and develop a plan for implementing lessons learned.%20LPS%205%20Steps-1.png)

The Last Planner® System is a realistic way to collaboratively manage project-based production. It enables issues to be identified and resolved and increases the chances that workflows and projects are completed on time.

Lean is a means to save your company money. It is a strategy by which we avoid making tradeoffs in time, cost, and quality. But don’t just take our word for it. Here are examples of real life projects completed under budget.

| Project |

Budgeted |

Actual Cost |

% Saved |

| Seattle Children’s Hospital |

$110,000,000 |

$79,000,000 |

28 |

| Orlando Chilled Water Plant |

$6,000,000 |

$5,400,000 |

10 |

| Toronto Office TI |

$11,250,000 |

$10,530,000 |

6.4 |

In addition to projects completed under budget, it is also possible to compare similar projects with different design systems. The projects below occurred at the same time, in the same city, with the same architect. The only difference is that the contractors used different delivery models.

These are the end results for two hospitals contracted by Universal Health Services.

|

Traditional Build |

Lean Build |

| Beds |

54 |

60 |

| Bid Amount |

$8,828,677 |

$8,206,072 |

| Change Requests |

30 |

3 |

| Change Order Costs |

$677,758 |

-$36,181 |

| Final Cost |

$9,500,000 |

$8,169,891 |

Construction companies that use the Last Planner® System have completed projects months in advance of scheduled completion date.

By planning in advance you avoid the typical all-out rush at the end of a project. By focusing on the overall goal of the project and not the speed of individual subcontractors, you can finish things faster.

This is best shown through real-life projects that finished ahead of schedule.

| Project |

Scheduled Completion (Months) |

Actual Completion |

| Seattle Children’s Hospital |

18 |

14 |

| Wisconsin Hospital |

38 |

36 |

| St. Louis Hospital |

26 |

24 |

| Toronto Tenant Finish |

14 |

8 |

| University Stadium East Stands |

10 |

8 |

See: http://themilitaryengineer.com/tme_mag/07_08_2013/TME-JulyAug2013-Online-SM.pdf.

Suffolk Construction has demonstrated savings in both time and money in two of their recent projects:

- Los Angeles Unified School District (LAUSD) South Region Middle School #3. The school was completed 2 months ahead of schedule AND saved approximately $1.05 million.

- Massachusetts College of Art and Design (Mass Art). After implementing Lean principles, Suffolk was able to cut 2 months off of the original project timeline.

There are many benefits to scheduling your project with the Last Planner® System. Changing your existing construction practices can be an intimidating process. When you have worked all of your projects the same way for years, it is difficult to make the switch. If you are still unsure if the Last Planner® System is right for you, here are some handy reasons why you should make the change as soon as possible.

With the Last Planner® System you will be able to:

Save money on projects

Deliver projects faster

Last Planner® does all of these things and more.

- Creates a more predictable and balanced workflow

- Reduces stress on project management staff

- Improves the overall production process

- Allows for mutual understanding between trade contractors

%20LPS%205%20Steps-1.png)